The drone turbojet engine is a miniaturized gas turbine engine that inherits the core principles of large turbojet engines, but has developed a series of unique technical features to meet the special needs of drones.

Overall, its core features are: small size, high power density, high speed, high integration, and low cost.

The following is a detailed analysis of technical characteristics:

Core performance drone engine characteristics

Extremely high thrust to weight ratio

This is the core advantage of turbojet engines. The thrust to weight ratio (the ratio of thrust to engine weight) is much higher than that of piston engines and turboprop engines. This makes it very suitable for drones that require high speed and maneuverability, such as target drones, reconnaissance drones, and cruise missiles.

Excellent high-speed adaptability

The turbojet engine has the highest efficiency during high-speed (usually above 0.8 Mach) flight. The design of the intake duct can utilize the “stamping effect”, where high-speed airflow is compressed and enters the compressor, allowing the engine to maintain strong thrust at high altitude and high speed. This is incomparable to piston engines and turbofan engines.

High working speed

The rotor speed is usually as high as tens of thousands of revolutions per minute or even over 100000 revolutions per minute (for example, micro turbojets can reach over 120000 RPM). This requires rotor components to have extremely high strength and dynamic balancing accuracy.

Structure and material characteristics

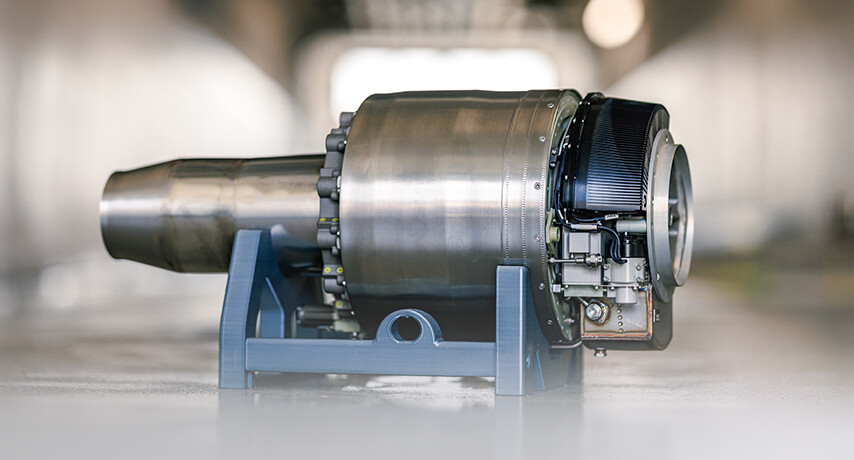

Highly integrated and simplified design

In order to reduce volume and weight, unmanned aerial vehicle turbojet engines (especially micro turbojets) typically adopt a single-stage centrifugal compressor and single-stage turbine design. Compared to the multi-stage axial-flow design of large engines, this has a simpler structure, greater robustness, and lower cost.

Radial intake and axial exhaust are common layouts with compact structures.

The extensive application of advanced materials

Compressor and turbine blades: High temperature alloys (such as Inconel 718) are commonly used to withstand gas temperatures of up to 1000 ° C.

Rotor components: Titanium alloys and composite materials are increasingly being used to manufacture compressor impellers and turbine discs to achieve lightweight and high strength.

Bearing system: Due to its extremely high rotational speed, high-performance ball bearings or ceramic bearings are required, along with complex lubrication and cooling systems.

Compact combustion chamber

Adopting a circular recirculation combustion chamber. The design of the flame tube and fuel nozzle is very compact, allowing high-temperature gas to burn fully in a limited space and be evenly directed towards the turbine.

Characteristics of control system

Full Authority Digital Electronic Control System

Almost all modern drone turbojet engines are equipped with FADEC. It is a built-in microcomputer responsible for precise control of:

Fuel flow: Accurately control the fuel supply based on throttle commands, flight altitude, speed, and environmental conditions to achieve stable combustion and smooth transition.

Start sequence: Control the starter motor, igniter, and fuel valve to complete the entire process from stationary to idle and then to stable operation.

Safety protection: Real time monitoring of key parameters such as engine speed (N1, N2), exhaust temperature (EGT), etc., automatic fuel reduction or parking when exceeded, to prevent engine damage.

High autonomy

FADEC makes engine operation very simple, and pilots (or ground stations) only need to control the throttle lever. The complex control logic is all completed by the computer, greatly reducing the difficulty of operation.

Characteristics of use and maintenance

Using aviation kerosene

Most drone turbojet engines use standard aviation kerosene such as Jet A-1, which is safer, more readily available, and has higher energy density than high-grade gasoline. Some models can also use diesel.

Start dependent on external power

It is necessary to start the motor (electric or pneumatic) to bring the engine to a certain speed before fuel injection and ignition can be carried out. The startup process requires high battery power.

High maintenance requirements

Although the structure is relatively simplified, high speed and high temperature require extremely high assembly accuracy, balance, and oil cleanliness. The turbine and combustion chamber are maintenance priorities and require regular inspection of the wear and tear of the hot end components.